The problem

During the height of the pandemic, door handles became a high-contact point of concern.

People were worried about catching germs, especially in public or shared spaces.

The need was urgent: a simple, durable solution that let people open doors without using their hands, and could be manufactured quickly and affordably.

Our goal

Design and prototype a foot-operated door opener that was easy to use, fit most commercial doors, and could be mass produced on-demand using 3D printing.

The design approach

We validated the concept through user surveys and rapid sketching.

Our team developed CAD models, ran structural tests, and used iterative 3D printing to refine the design.

Key design principles:

- Universally compatible with standard door bases

- Easy to install and use with any footwear

- Durable enough for high-traffic public settings

- Cost-effective and fast to manufacture

What we built

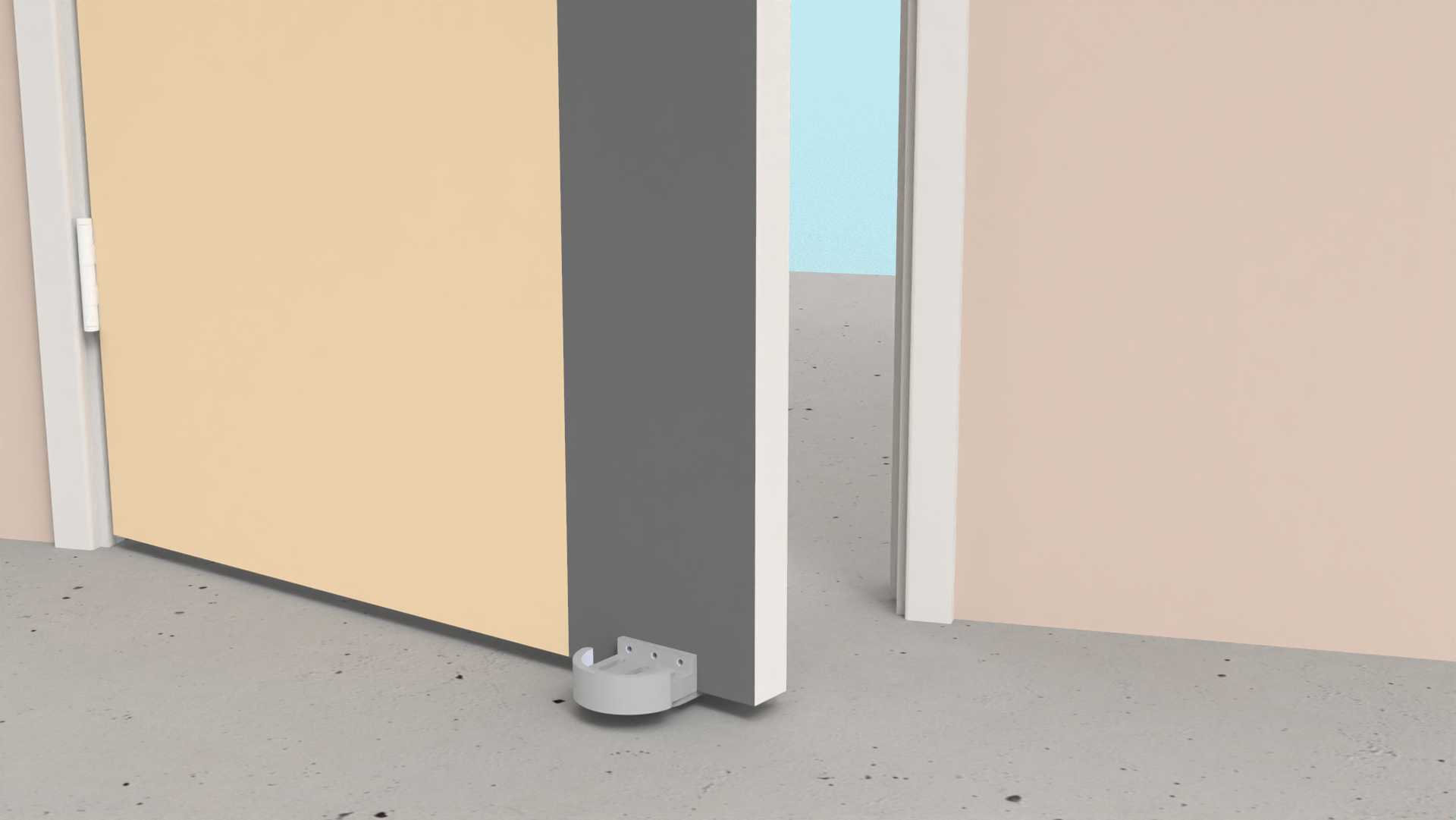

The result was Footsie, a compact, foot-activated door opener.

Our prototype featured:

-

-

- A curved, grip-friendly form that fits most shoes

- 3D printed with reinforced material for strength and durability

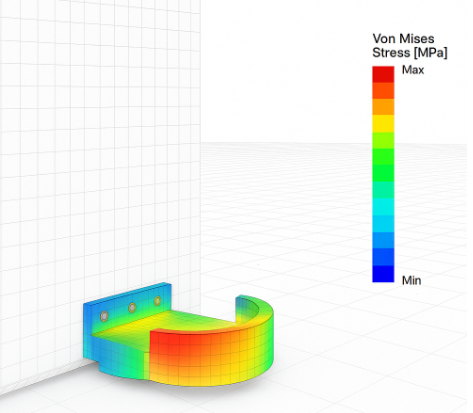

- Stress-tested using simulation tools to ensure long-term use

- Designed for no-touch operation to reduce germ transmission

- Rapid prototyping cycle completed in under 2 weeks from concept to functional unit

-

Tools and techniques used:

-

-

- Fusion 360 for design and stress testing

- FEA simulation for structural validation

- 3D printing for prototyping and low-volume manufacturing

-

Outcome

Footsie was awarded and recognised as a smart public hygiene solution.

Interested in starting your project?

Check your numbers in under two minutes and compare them with what similar firms get through Xynapse.