The problem

An educational product company wanted to create eco-friendly STEAM kits for children but faced three major challenges:

- Converting sawdust waste into a safe, usable material.

- Designing hands-on projects that were fun, educational, and child-safe.

- Ensuring all components were precise, consistent, and easy to assemble.

They needed a low-waste, scalable way to produce physical kits from recycled material, without compromising safety, usability, or learning value.

Our goal

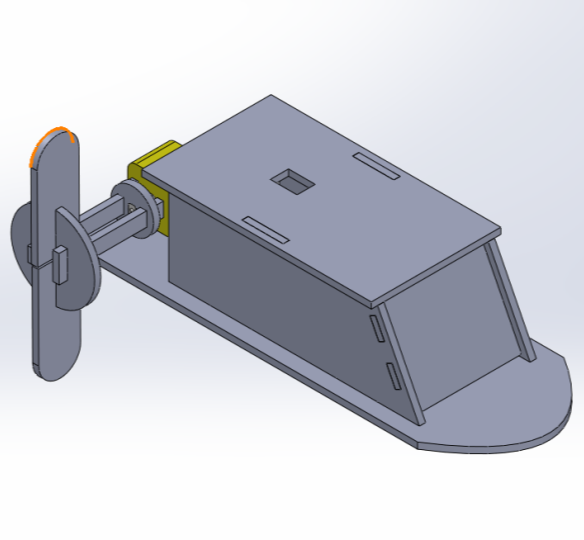

Design and prototype a durable, engaging DIY kit using upcycled sawdust boards, with laser-cut components suitable for young learners.

The design approach

We approached this project with the utmost understanding of the impact it will have in the real-world, and thus, the need to design and develop with sustainability first.

Key design principles:

- Repurpose sawdust into sturdy sheet material.

- Design STEAM kits that encourage creativity and problem-solving.

- Ensure parts are safe, child-friendly, and easy to handle.

- Use digital fabrication for accuracy and repeatability.

What we built

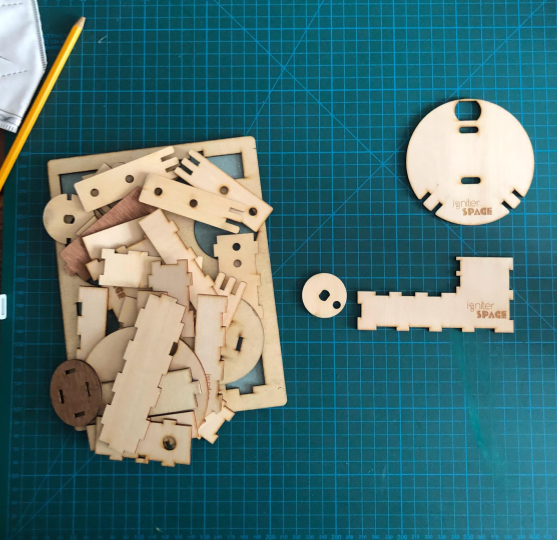

Our prototype included:

-

-

- Recycled boards made from compressed sawdust.

- Multiple child-friendly STEAM projects designed in-house.

- Laser-cut components for precision and easy assembly.

- Instructions tailored for kids and educators.

- Built and tested over a 3-month period, from raw material R&D to kit production.

-

Tools and techniques used:

-

-

- Fusion 360 for CAD design.

- Laser cutting and 3D printing for prototyping.

- Material testing to ensure durability and safety.

- Small-scale production for pilot classroom testing.

-

Outcome

The project proved that waste material can fuel hands-on learning.

The kits were well-received in early tests.

Interested in starting your project?

Check your numbers in under two minutes and compare them with what similar firms get through Xynapse.